infraTest

AUSTRALIA

infraTest Testing Systems

Test Systems for Bitumen, Asphalt, Soil, & Concrete.

infraTest in Australia

Vtech MTE is proud to offer a full range of these world class test systems for quality assurance, research & development of asphalt, bitumen, concret & soil.

Vtech MTE – authorised supplier of infraTest equipment in Australia.

- Complete Product Range

- Delivery Throughout Australia

- Ongoing Support

- Industry Expertise

- & More

Featured Product: Asphalt Analyzer YOU! Touch

Wide Range of infraTest Products

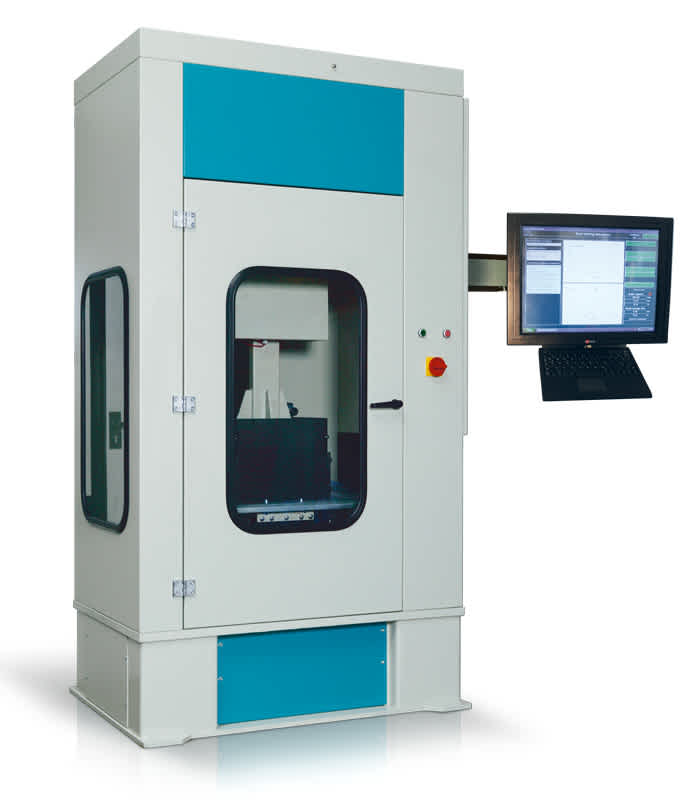

ROLLER SECTOR COMPACTOR | Asphalt

Roller Sector Compactor 30kn

Roller Sector Compactor 30 kN for the preparation of rolled asphalt samples.

Rigid steel housing with safety door and motor-driven sample guiding unit. Compaction load is applied horizontally by an electronically operated load/displacement controlled system with a roller segment and load and displacement transducers.

Mould and roller segment are equipped with thermostatically controlled electric heating elements.

The whole process is controlled by selectable compaction programmes via Windows software. The user himself can create and memorize own test sequences. The machine and process control is effected by an integrated input/output unit with a touch screen attached by means of a swivel arm. Optionally the input can also be effected using a keyboard.

Sample dimensions available:

20-4030 / 320x260mm

20-4035 / 400x300mm

20-4031 / 410x260mm

20-4034 / 455x300mm

HAMBURG WHEEL TRACKER | Asphalt

Hamburg Wheel Tracker

Advanced asphalt performance testing.

Wheel Tracking Test Apparatus air/water small wheel for asphalt samples. The apparatus consists of a steel plate casing with stainless steel interior 1.4301 and hinged cover with viewing glasses.

Two measuring places with rolling wheel units guided in precision bearing elements and driven by a frequency-controlled motor with omega-synchronous-belt-drive are installed. The load is applied via a lever system. The inner chamber can be heated either with water or with a heating system.

To enable the installation of samples into the testing place, both rolling wheel units can be stopped in a parking position outside the testing area. The two sample base plates of the machine are prepared for the installation of either mould spanner sets (20-4020..23) or plaster moulds (20-4015..16). Included are two easily interchangeable rolling wheels with rubber coating.

Stainless steel rolling wheels 20-4000E100 are available on request. Two motorized lifting units controlled by the integrated software are used to sink down the wheels at the beginning of a test and to lift them up afterward. The whole process including heating, registration of test temperatures, number of overrollings and tracking depths is software controlled with the possibility of print-out and selectable testing programmes. The user himself can create and memorize his own test sequences and programmes.

Supplied with integrated input/output unit with a touch screen. Optionally the input can also be effected using a keyboard. Mould spanner sets 20-4020..23 or plaster mould sets 20-4015..16 are not included and have to be ordered in addition.

AUTOMATIC DIGITAL PENETROMETER

Automatic Digital Penetrometer

For determination of the needle penetration.

The penetration depth of the penetration needle is determined with an electronic position measuring system, which is decoupled from the plunger during the test. An influence on the load and friction is excluded, because of this the free guidance of the plunger.

The run-up and touch down of the needle are carried out automatically via the measurement system. Manual joystick mode is also possible. Then the plunger is enabled by an automatic device and blocked again after the testing period. The test result is displayed on the graphical touch display. The plunger can easily be removed to calibrate its weight.

Technical specifications:

Measuring range: 0-300 (equivalent to 0-30 mm)

Resolution: 0,01 mm

Test load: 100 g (plunger 97.5 g + 2.5 g penetration needle)

Test time: free (adjustable from 0,01 second)

EN 1426 – EN 13880-2/3 – ASTM D 5 – AASHTO T49

ASPHALT ANALYZER PURE

Extraction and binder content determination of bituminous materials begins here. Bituminous material (up to 3.5kg) is weighed into a sieve drum and placed into the washing chamber.

User selects the needed amount of washing and drying cycles and materials will be automatically washed and separated into aggregates, mineral filler and binder under use of solvents and ultrasonic sound separation. The aggregates remain in the sieve drum.

Mineral filler is separated from binder and solvent in the centrifuge unit.

The mineral filler is collected in the centrifuge cup and the binder-solvent mixture is concentrated in the recovery unit by distillation. The recovered solvent is collected in the recovery chamber. Mineral aggregates and filler are dried in the machine and are provided for weighing and the determination of the grading of the bituminous mixture.

The Pure Module is equipped with indirect heating system, which allows a careful and safe handling of the used solvents which are recycled after each extraction.

Asphalt LABORATORY MIXER

Laboratory Mixer 30 l, 400 V, 50 Hz for preparation of bituminous material mixture samples according to the synchronisation principle. The cover with sealing is equipped with a spindle motor to open and close.

A window allows watching the mixing process inside. This window can be replaced by the optionally available funnel 20-0160E10.

In addition, the cover is provided with connection plugs for gas etc. The constant speed motorized stainless steel mixing drum is equipped with a switch to turn left or right. An electric heating installation at the bottom and walls with PID regulator provide a constant temperature.

For unloading, the mixing bowl can be tilted to the front by the installed motor system. The special mixing tool with variable speed range is optimized for mixing asphalt samples.

Specifications:

Drum contents 30l

Mixing tool speed 25..60 1/min

Mixing drum temperature 25..250° C

Dimensions approx. 1015x1015x1490 mm

Electrical data: 400 V, 50 Hz, 3 P+N+PE, 12 kW

Standards EN 12697/35 • ASTM D 1559

Weight approx 515kg

BENDING BEAM RHEOMETER

20-44220

BBR Bending Beam Rheometer. Test System for Determination of Flexural Creep Stiffness of Asphalt Binder at low temperatures. The flexural strength, among other things, is determined in order to evaluate the behaviour of asphalt binder and similar products at low temperatures.

The bending beam rheometer enables users to determine these material properties comfortably. The deflection of the specimen is measured for this purpose with a resolution of 1µm. The test force is regulated with an accuracy of 1 mN. This makes the determination of the flexural strength possible with reproducibility of 1% independent of the operator. The specimen unit is moved by an electromotor and makes fitting and removing the specimens uncomplicated and simple. Automatic, software-controlled operating and standardised evaluation and representation of the findings.

The automatic system monitoring contains various diagnosis functions and prepares the required diagnosis records. Performance features:

-Integrated programmable controller for controls and recording measured data

-Compact tempering unit with heater and compressor cooling and powerful pressure/suction pump

-Temperature range: -40…+200°C

-Resolution ±0.01 K -Freely selectable test temperatures

-Separate test bath with constant level maintenance

-Linear-electromagnetic loading unit, max. lift 10 mm, max. force 2000 mN

-Incremental transducer, accuracy better than 1 μm

-Load cell accuracy class 0.1 (better than ± 0.1%)

-Force control better than 1 mN

-Working range 0 … 1500 mN

-Own layout of test records

-all Test Data as CSV-file available

Technical data:

-Dimensions: (HxWxD) 1500 x 650 x 600 mm

-Width 1200 mm including PC on the bracket

-Weight: approx. 80 kg without accessories

-Weight thermostat: approx. 60 kg -Test bath: approx. 11L

-Bath liquid (recommended): Ethanol, 95 %

-Mains connection: 230/240 V, 50/60 Hz

-Output: 2000 VA

Specifications:

Electrical data 230/240 V, 50/60 Hz, 2000 VA

Dimensions approx. 1500x650x600 mm

Weight approx. 80 kg

Standards DIN EN 14771 • NF T 66-062 • ASTM D 6648 • AASHTO T 313

ASPHALT GRANULATOR

20-1440

Asphalt Granulator to prepare samples for bulk density tests. An asphalt sample of up to appr. 1 kg is put into the apparatus at room temperature and is mechanically crushed to a granulate which can be used in pycnometer bottles for bulk density tests using water acc. EN 12697/5. Supplied including Sound protection and cushions for the lid, holding frame for stainless steel tray 95-2044 (tray not included) and timer 0-60 min.

Specifications:

Electrical data 230 V, 50 Hz

Standards EN 12697/5

Weight approx. 85 kg

PARALLEL GRINDING & CUTTING MACHINE

450mm

60-1200

Parallel Grinding and Cutting Machine 450 mm with two electric motors equipped with diamond grinding heads for simultaneous plane-parallel grinding of the specimen. Both grinding units can be finely adjusted to achieve parallel sample surfaces.

The samples are fixed on an electric driven movable carriage with variable speed range. The diamond grinding heads are equipped with cooling water connection for town water installation.

Supplied with industrial safety cover and clamping device for cubes 100 up to 150 mm and cylindrical specimen Ø 100 up to Ø 150 mm. Clamping devices for cubes 50 mm, cubes 200 mm and cylindrical samples Ø 50 mm are available as an option. Supplied with cutting head for diamond saw blades 450 mm dia. If required, a second diamond saw blade can be attached with variable distances from 25 to 60 mm.

This installation is suitable to cut particularly prismatic samples out of sample plates up to 410 x 260 x 120 mm. Two diamond grinding heads 210 mm dia. 60-12200 for bituminous mixtures resp. 60-12210 for concrete as well as diamond saw blades 450 mm dia. 60-12300 have to be ordered in addition.

Specifications:

Clamping device for cubes 100 up to 150 and cylindrical samples 100 up to 150 mm dia.

Sample length min. 50 mm

2 x 3 kW for grinding, 4 kW for cutting

Dimensions approx. 1850 x 2150 x 1720 mm (height = 2230 mm when safety cover opened)

Electrical data 400 V, 50 Hz, 16 A, 2×3 kW, 4 kW

Dimensions approx. 1850x2150x1720 mm

Weight approx. 900 kg

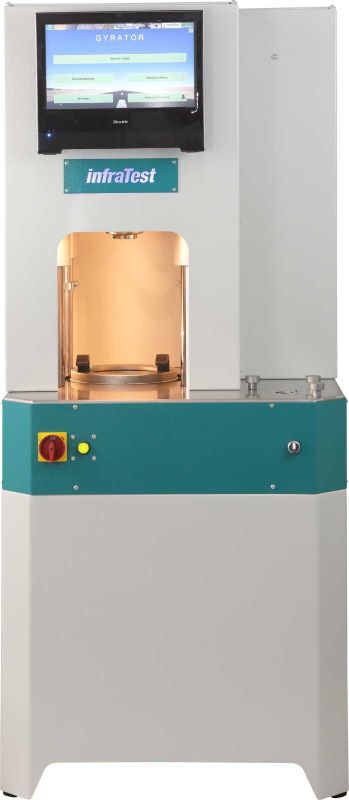

GYRATORY COMPACTOR | Asphalt

Gyrator iT 2018 for preparation of gyratory specimen with diameter Ø 100 and 150 mm Standards: ASTM 6925-15, ASTM 7515-10, EN 12697-31

⦁ fully automatized gyratory compaction and rotation

⦁ Drive electromechanical

⦁ Measurement by an integrated load cell

⦁ integrated sample extruder with a sample table

⦁ control by integrated computer for automatic compaction

⦁ including evaluation report for sample preparation

⦁ integrated Ethernet port for remote distance control

⦁ Angle adjustable by software

Specifications:

Power Supply: 400 V, 50/60 Hz, 3 P+N+PE

Compaction Load: 1000 kPa

Power: 7 kW

Ram travel: 10 mm per second

Ports: 1x USB, 1x RS232, 1x Ethernet

Speed: up to 30 rpm (±0,5°)

Angle: adjustable 0,5 up 2°

Sample size: Ø 100 and 150 mm

Dimension: 803 x 703 x 1800 mm

Standards: ASTM 6925-15, ASTM 7515-10, EN 12697-31

Weight: approx. 538 kg

Automatic Ring and Ball Tester

EN 1427 – ASTM D36 – AASHTO T53 – GOST 11506-73

For determination of the Softening Point of Bitumen.

With glass-ceramic plate, halogen radiator for heating and magnetic stirrer with adjustable speed built-in underneath.

Operation is via a touch panel. A microprocessor-controlled regulation with continuous temperature measurement in the beaker ensures a standard-compliant temperature rise of 5 K/min. The temperature rise can be monitored in real-time on the touch display.

The passage of the balls is detected by a light barrier on the right and left and the respective temperature value is displayed digitally. At the same time, the difference between sample 1 and 2 is output. The test data is stored in an internal protocol and can be called up at any time in the unit or transferred via a USB interface.

Three test modes can be preselected, one for water from 30 to 80° C and one for glycerol from 80 to 150° C. Besides, we offer an optional test procedure for silicone oil from 80 to 200°C.

Complete with beaker 600 ml, stirring rod and insert frame with 2 test rings, test balls and 2 ball centring devices. The user languages are German, English and French.

SCUFFING DEVICE 2018

EN 12697-50B

For the determination of scuffing resistance of asphalt surface layers acc. EN 12697-50 Part.B

Contains:

- Test frame with wheel loading piston

- Test with vertical measuring unit and automatic loading unit

- Heated sample mould 260x260mm

- Driving motor with a Rotating-Drive Unit for a continous wheel sample contact

- Test frame with transparent safety guard

- Measuring and data aquisition of the surface sample temperature by IR-Thermometer

- Exhaust Device with cyclone separator for grains

- Control via PC

- Test configuration with free programable test option (Cycles, Speed, Load, ….)

- Pressure Supply min. 5 bar

Get in touch today by phone or send us a message using the contact form below.

Call +61 3 9404 2610